|

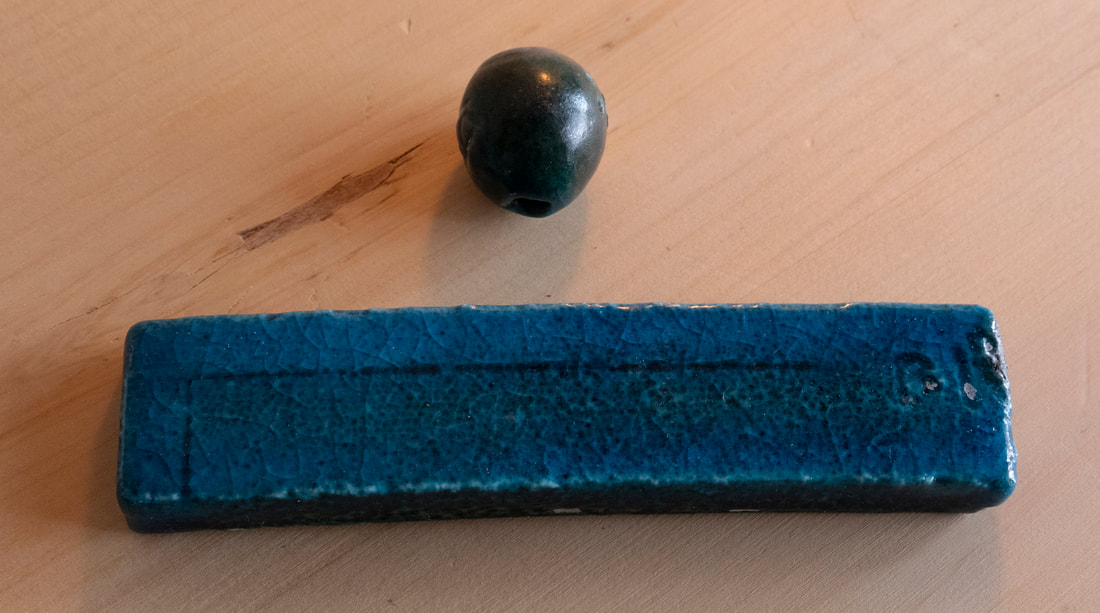

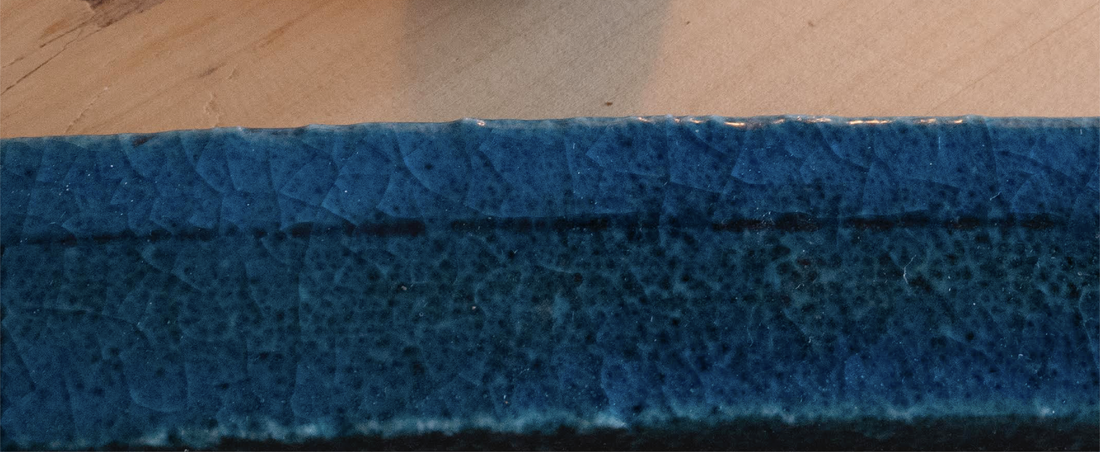

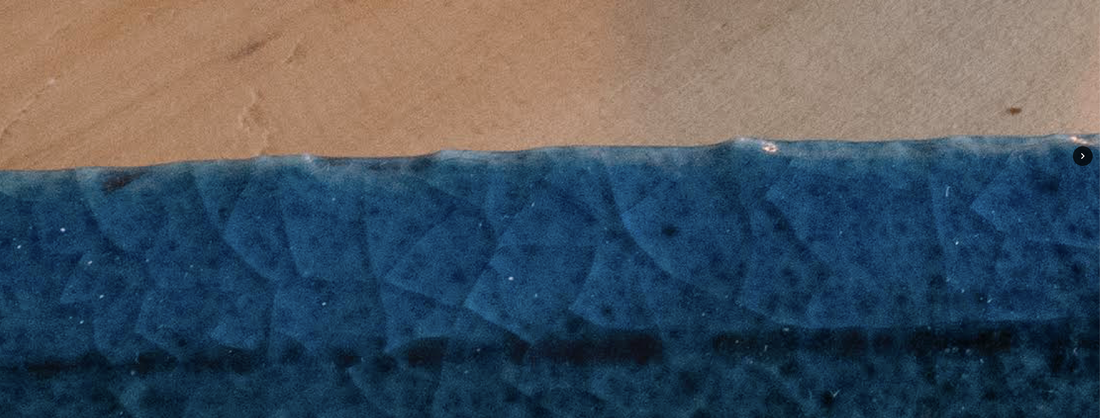

Tasks Accomplished previously: The last firing, cone 04, resulted in a sugary coating like an under-fired glaze. I don't have a photo. Tasks to accomplish: 1. increase glass at cone 04. 2. develop colour. 3. measure linear shrinkage. References: Alan Caiger-Smith, Robin Hopper, John Britt, Amy Waller Observations & Reflections I left the test bar for paste 'B1' (Fig.1) to dry for two to three weeks, much longer than I normally would. I noticed shortly before firing that the efflorescence seemed thicker than usual, and the blue more intense than usual. It's clear that there is more efflorescence with the passage of time. I will experiment with length of drying time. The test bar for B1 resulted in a deep, intense copper blue. I quite like it. You can see on the bead (Fig.1) that the oxide percentage may be a little too high; it's flat black in places. I used 3.5% copper carbonate; however, drying time seems to be a factor that increases the saturation of the colorant. The crackle pattern is appropriate for a decorative object, providing an engaging break-up of light. There is the possibility of staining the crackle. The surface is still filled with micro-discontinuities, which a soak would likely cure, or going up one cone, to 03. The test bar is tricky to read for shrinkage. Shrinkage bars are fired without glaze, so it's easy to read the measure. But here there is no "without glaze", so it is a bit tricky to read the measure. It looks to be 14% shrinkage which seems high. I will have to make better marks. Workability is not awful, but I did not push it. You can see in the pic below that it takes a ragged edge which means relatively low plasticity and limited workability. It is also somewhat friable when dry. I think it needs some bones. Robin Hopper's Egyptian Paste ^08

Feldspar 36%. Silica 18 Kaolin 14 Ball clay 5 Sodium bicarbonate 5 Soda Ash 5 Calcium carbonate 4 Fine white sand 7 Bentonite 4.5 98.5% Flux: 50, Silica: 18, Clay 23.5 John Britt's Egyptian Paste ^06: Soda feldspar 38 Silica 38 Ball clay 12 Soda ash 6 Sodium bicarbonate 6 100% Flux: 50, Silica: 38, Clay: 12 I decided to fire toward the upper end of the Egyptian paste range, about ^04. If you look at Hopper's slides, his glaze is sugary, not glassy, and it has large visible discontinuities. Britt's on the other hand is closer to what I want, a more continuous glass surface. I don't see a reason for Kaolin, it will make it more refractory, and I would in any case choose a more plastic clay, keeping in mind that its iron content must be as low as possible. So I came up with the following mix, B1 (fig.1), as a starting point: ^04 F3110. 4.3 Neph Sy 30.5 Soda Ash (lite) 10.5 Silica (400M). 30.5 OM4. 17.5 Vee Gum T 3.5 CuCo3 3.5 Flux: 45.3, Silica: 30.5, Clay: 21 It combines aspects of both Britt's and Hopper's formulae. B1 is much higher in silica like Britt, and much higher in clay, like Hopper. I think clay is going to be important for a decent range in workability, and some bones to help knit the body together.It could be interesting to try splitting the Silica between two grades of silica, 25% very fine and 5.5% course. This would open up the pore structure, which in turn could encourage efflorescence. Temperature at 04 seems fine. Could use a longer soak. Tasks accomplished: 1. Increased the glassiness of the surface 2. Developed an intense turquoise blue 3. Shrinkage is probably at 14% Task to accomplish: 1. Increase plasticity 2. Decrease friability 3. Test for different drying times: 1 week, 2 weeks, etc 4. Decrease soda ash 5. Redo shrink bar (use calipers) 6. Do an absorption test

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

RSS Feed

RSS Feed